Appel 17

R&D

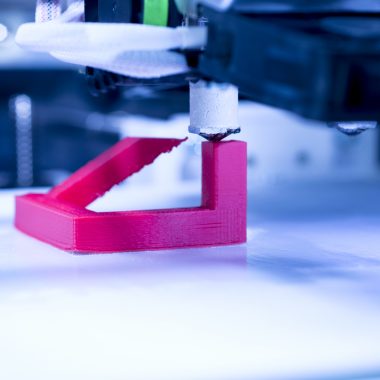

Le projet CALFDM vise à développer un logiciel de simulation et de caractérisations permettant d’évaluer les propriétés mécaniques et de s’assurer de la résistance fonctionnelle de composants fabriqués en impression 3D.

Le procédé de fabrication additive par dépôt de fil fondu (FDM), aussi appelé impression 3D, est aujourd’hui communément reconnu comme étant partie intégrante d’une nouvelle révolution industrielle. Ce procédé est complémentaire aux procédés conventionnels car il permet d’adresser des géométries irréalisables par moulage et usinage, et de pouvoir fabriquer des pièces sans outillages. La fabrication additive offre d’énormes gains en délais d’exécution et en coût final des produits.

Toutefois, l’adoption dans les secteurs Aérospatial, Défense, Industrie et Automobile de cette technologie pour les pièces mécaniques à haute valeur ajoutée est empêchée par le manque de moyens de dimensionnement permettant de prédire le comportement mécanique des pièces produites.